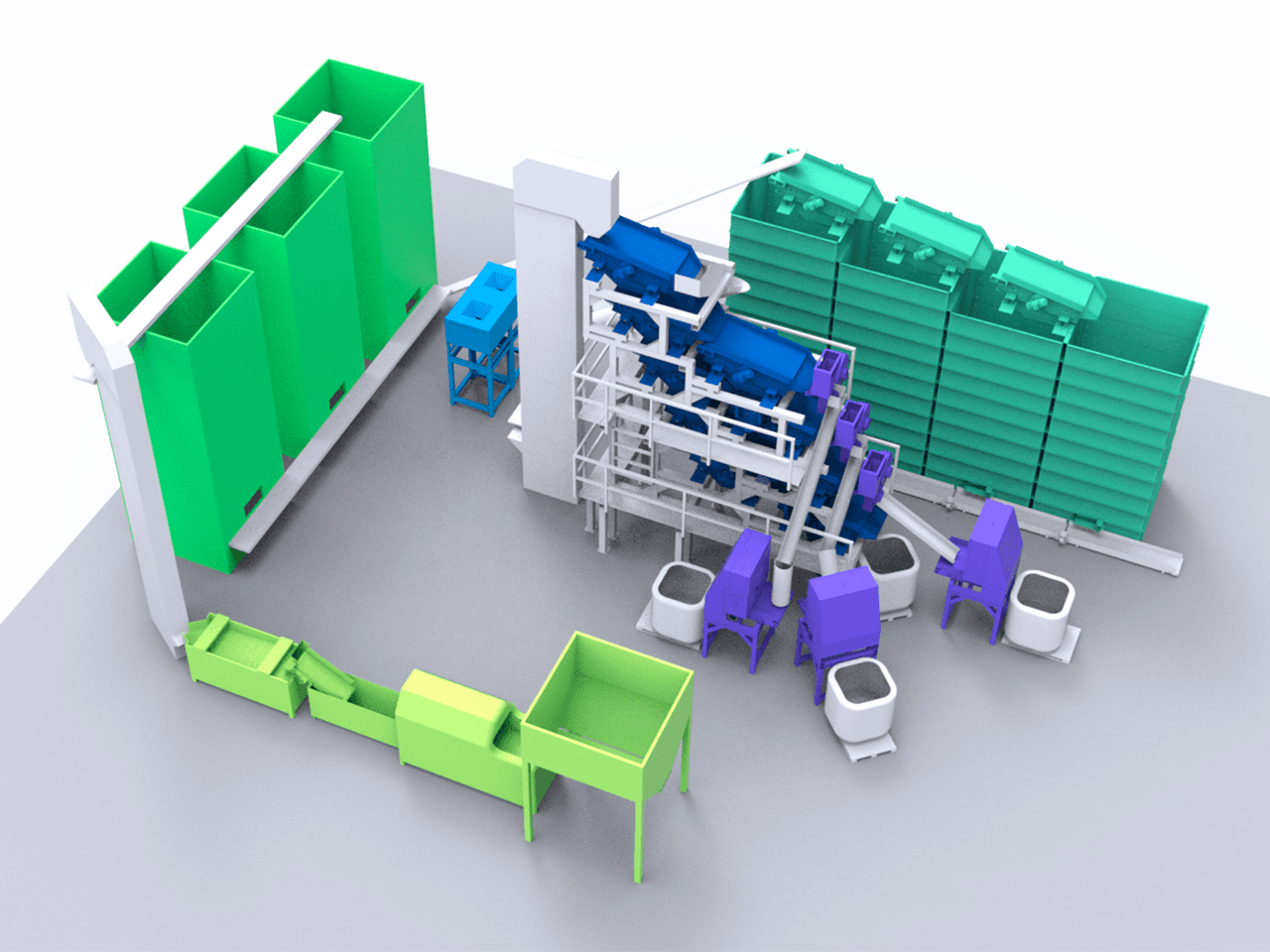

TURN-KEY PROCESSING PLANT

Complete Automated Processing Plant for Shelled Fruits

KRAPCO specializes in supplying fully automated complete food processing factory for shelled fruits, offering a comprehensive range of technologies to support every stage of production, from nut washing and cracking, calibrating and sorting, right through to the final packaging. Our offerings include pick-and-place machines, optical hyperspectral, mechanical or aerodynamic sorting machines, nut cracking machine, as well as associated accessories tailored for the food industry and other industrial sectors. Technical solutions are always dimensioned to meet all user-specified qualitative and performance parameters, while also providing After-sales services. The price of the Processing factory depends on the desired capacity and processing scope.

The significant benefit of the implementation is that only two production operators are needed to ensure the proper functioning of the machines and control the entire processing factory.

PROCESSING STAGES

The first step involves the removal of green husks and other impurities from walnuts in the shell. The walnuts are then washed and cleaned in water, with stones and other impurities being removed. The product transport is ensured by CONV2000 conveyor belts.

The washed and cleaned walnuts in the shell are dried using hot air to eliminate excess moisture.

Walnuts in the shell are calibrated, and any remaining impurities are removed using MFS800 sieves. The walnuts are then stored in SILOS2000 according to their size, for example 30-32 mm, 32-34 mm, and 34+ mm.

Cracking the walnuts is ensured by specialized nut crackers CRACK1000. Walnuts that are inadequately cracked are returned to the cracking process.

Cracked walnuts are transported toa conveyor system, where on a calibration tower, the walnuts are sorted by size, depending on the desired fractions, using MFS800 sieves.

The initial sorting process takes place on the calibration tower using BLOW1000 blowers, which remove dust, husks, and partially shells. Each output from the tower then undergoes further sorting using Walso HSI optical hyperspectral sorters, which reliably remove any remaining shells and impurities from the walnuts. The walnuts are now prepared for further processing or packaging.

Gallery

;

; ;

; ;

; ;

; ;

; ;

; ;

; ;

;